4 MORRISON POWER BUGGY FEATURES YOU DON’T WANT TO PASS UP

Power Buggies have been around for many years now, and regardless of the make or brand, they all do essentially the same thing; move material around your job site quickly and efficiently. It can be difficult to know which brand or model to invest in when they all are created for the same purpose. After receiving many questions, we thought it would be a good idea to put together a helpful list of features that are important to consider when investing in a power buggy. These features will make maneuvering the job site and maximizing efficiency, that much easier.

1) THE BUCKET

The bucket on your power buggy is one of the most important parts. Because you’re using it to transport so many different types of material, having a properly designed bucket will make all the difference.

One problem you’ll often find with poly buckets, is that when it is filled with certain materials, the sides can bow out. This not only and issue because it increases the risk of breakage but also, because it increases the width of your buggy, making it more difficult to fit through doorways or tight spaces. We know how annoying that can be as an operator, that’s why we designed our DB17 high Density Poly Bucket with greater strength and rigidity to hold its shape and prevent bowing.

Another main use of a power buggy is to transport wet concrete around the job site. Wet concrete can easily slosh around as you drive. Without a properly designed bucket, you can end up losing some of your material as you transport it around the job site. Additionally, a properly designed bucket will help prevent the material from waving up over the back onto the motor and the operator. Not having a properly shaped bucket will not only make a mess, but can decrease production speed and can even end up costing money in wasted material.

Morrison's poly bucket has more pronounced roll back lip than any other buggy on the market. It was designed that way to prevent the issues noted above from occurring. The shape and angleat the front of the bucket also helps to hold material in from sloshing out the front without impairing the pouring aspect of the machine.

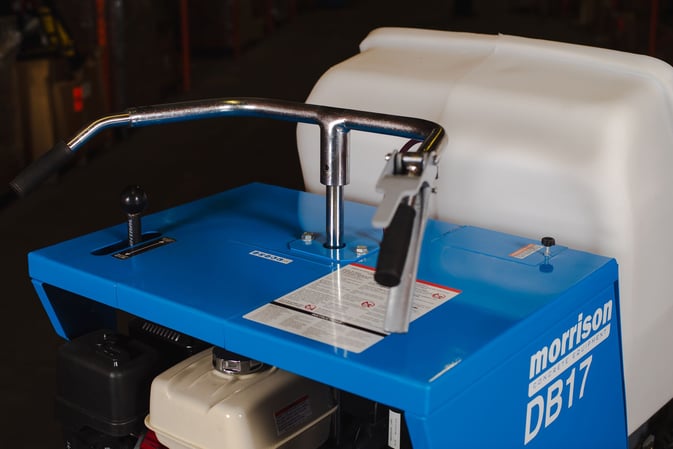

2) FORWARD & REVERSE RIGHT ON THE HANDLE

Many concrete buggies out there have the forward / reverse control located down by the engine. This positioning makes transitioning from moving forward to reversing the buggy more difficult. The Morrison Concrete Buggy has the forward and reverse function built right onto the handle. Not only is this more user ergonomic and user friendly, it allows the operator to switch from forward to reverse with ease. This makes moving around the job site much easier.

3) FREE-WHEEL MECHANISM

One of the most annoying things that can happen with a power buggy, is when it runs out of fuel. It’s easy to lose track of time on a busy job site when there are a million things to be done, so running out of fuel at the most inconvenient time can happen. When this happens, with most buggies you are unable to move them without lifting them due to the hydraulic drive systems that are commonly used. These buggies can only be moved when turned on, but without fuel, they can’t be turned on. Having to stop what you’re doing to go get a fork lift, drive it over to where the buggy is, and drive it back to fill it up with fuel is an annoying setback.

The Morrison power buggy has a Free Wheel Mechanism or a, “Neutral Control Cable” built in, which allows the operator to move the buggy without needing to turn it on. This is one of the key features that these buggies have as it can help in many situations. Even just being able to move the buggy 5 ft. forward in your shop without having to start it is a benefit.

4) STEP PLATFORM

This is part of the machine that people tend to overlook- but the added features that have been added to the Morrison DB17 step platform are super helpful in a few different situations.

First, you’ll notice in the picture below that there is an incredible amount of space to stand on, this is key for operator comfort and safety.

Additionally, because we recognize that the extra space can get in the way when maneuvering around tight spaces or when driving on an incline, we’ve added a hinge (see below) so you can fold the platform in half. Not only does that maximize maneuverability but it also allows for an additional few inches of height for those who need it.

Is your business ready for a Concrete Buggy? Read more here.

The Morrison Power Buggy has some great features that make it very productive around the job site, and extremely operator friendly. At the end of the day, most of the buggies on the market are quite similar in theory, but with these few extra features, the Morrison Buggy offers a much better experience overall.